Control Standard for Electrical Power Transformer Installation Process

1. The basic track horizontal error is <3mm, the center deviation is <5mm, the insulation pad is ≤3 pieces per point, the welding is firm, and the two points of the track are grounded.

2. The lateral center deviation of the transformer body is ≤ 20 mm, the roller is flexible, and the roller brake is assembled firmly. The bell housing and the lower part of the fuel tank are grounded.

3. The transformer bell housing and the lower part of the fuel tank are grounded at not less than 2 points.

4. The ground of the transformer body is grounded at two points in different locations on the main ground network.

5. The iron core and the coil are intact, the insulating block is dense and loose, the oil circuit is not blocked, the insulation layer is evenly wrapped, the nail is fastened, and the lock nut is locked.

6. The tap changer leads are correct and firm, the contact is clean and flexible, the plug feels not inserted (0.05×10mm), the position of the switching device is correct, and the rotary shaft is operated evenly and flexibly.

7. The on-load voltage regulator must be implemented in strict accordance with the manufacturer's instructions.

8. There is no dirt and debris at the bottom of the box, the bell jar is fixed with anti-magnetic baffle, the flange is butt jointed, and the bolt tightening force is uniform.

9. The appearance of the casing is free from scratches, cracks and porcelain. The oil level is on the oil line and there is no leakage. There is no water and dust in the pressure equalizing hood, and the connection is tight.

10. The sleeve installation sealant ring is evenly compressed without leakage. The oil level indication is normal and the oil mirror direction is correct.

11. The gas relay installation arrow mark points to the oil pillow side, the vertical and horizontal axis is horizontal, and the verification fixed rope is removed in the relay, making the action flexible and reliable.

12. The appearance of the oil conservator is free from scratches and cleanliness, and the bellows is intact.

13. Raise the seat, connect the oil pipe, the radiator and other connecting ports, and the connecting bolts are tightly stressed.

14. Cooling fan motor, the insulation test of the submersible pump motor is flexible and the rotation direction is correct.

15. For the body inspection, the oil test must be done first. After passing the test, the core can be inspected. When the relative humidity of the air is less than 75%, the body should not be exposed to the air for more than 16 hours.

16. Gas relays and thermometers can be installed after passing the inspection.

17. The low-pressure side soft copper sheet phase and ground distance meet the specifications. The leads are securely connected and non-magnetic bolts are used.

18. The transformer vacuum check and pressure check can be carried out according to the manufacturer's requirements.

19. The transformer high-voltage lead wire is fastened to the casing connecting bolt, and the electric grease is applied before the lead copper rod is connected to ensure good contact.

20. After the oil is completely oiled for 48 hours, the oil sample can be taken for inspection.

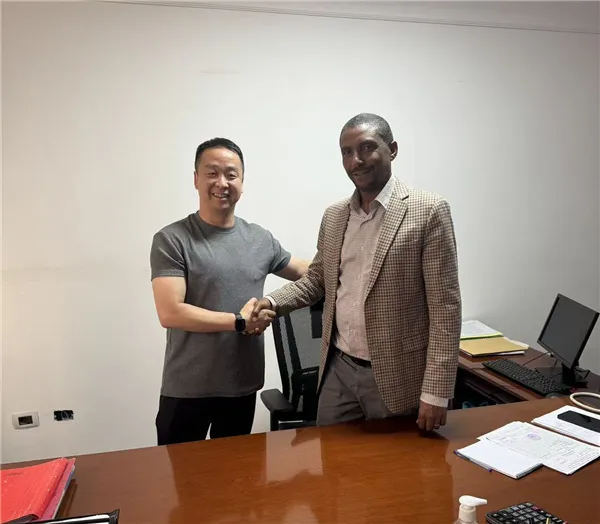

Welcome to buy the electrical power transformer of YueBian Electric Co.,Ltd.

2. The lateral center deviation of the transformer body is ≤ 20 mm, the roller is flexible, and the roller brake is assembled firmly. The bell housing and the lower part of the fuel tank are grounded.

3. The transformer bell housing and the lower part of the fuel tank are grounded at not less than 2 points.

4. The ground of the transformer body is grounded at two points in different locations on the main ground network.

5. The iron core and the coil are intact, the insulating block is dense and loose, the oil circuit is not blocked, the insulation layer is evenly wrapped, the nail is fastened, and the lock nut is locked.

6. The tap changer leads are correct and firm, the contact is clean and flexible, the plug feels not inserted (0.05×10mm), the position of the switching device is correct, and the rotary shaft is operated evenly and flexibly.

7. The on-load voltage regulator must be implemented in strict accordance with the manufacturer's instructions.

8. There is no dirt and debris at the bottom of the box, the bell jar is fixed with anti-magnetic baffle, the flange is butt jointed, and the bolt tightening force is uniform.

9. The appearance of the casing is free from scratches, cracks and porcelain. The oil level is on the oil line and there is no leakage. There is no water and dust in the pressure equalizing hood, and the connection is tight.

10. The sleeve installation sealant ring is evenly compressed without leakage. The oil level indication is normal and the oil mirror direction is correct.

11. The gas relay installation arrow mark points to the oil pillow side, the vertical and horizontal axis is horizontal, and the verification fixed rope is removed in the relay, making the action flexible and reliable.

12. The appearance of the oil conservator is free from scratches and cleanliness, and the bellows is intact.

13. Raise the seat, connect the oil pipe, the radiator and other connecting ports, and the connecting bolts are tightly stressed.

14. Cooling fan motor, the insulation test of the submersible pump motor is flexible and the rotation direction is correct.

15. For the body inspection, the oil test must be done first. After passing the test, the core can be inspected. When the relative humidity of the air is less than 75%, the body should not be exposed to the air for more than 16 hours.

16. Gas relays and thermometers can be installed after passing the inspection.

17. The low-pressure side soft copper sheet phase and ground distance meet the specifications. The leads are securely connected and non-magnetic bolts are used.

18. The transformer vacuum check and pressure check can be carried out according to the manufacturer's requirements.

19. The transformer high-voltage lead wire is fastened to the casing connecting bolt, and the electric grease is applied before the lead copper rod is connected to ensure good contact.

20. After the oil is completely oiled for 48 hours, the oil sample can be taken for inspection.

Welcome to buy the electrical power transformer of YueBian Electric Co.,Ltd.

Jump to Content Sections

Leave a Message

You May Also Like

English

English  français

français  Español

Español  русский

русский  العربية

العربية  tiếng việt

tiếng việt  Malay

Malay  Indonesia

Indonesia  বাঙালি

বাঙালি